A Guide to Custom Metal Stampings and Zinc Die Casting Manufacturing

Metal stamping is all about establishing a point. This process uses designed tools and dies to shape flat sheet metal into desired forms. Due to high demand, many brands prefer something extra. To achieve this, they usually prefer customized services. Today, we will introduce you to custom metal stampings and zinc die-casting manufacturing. We will cover every aspect of these topics, from basics to advancements.

What is Metal

Stamping?

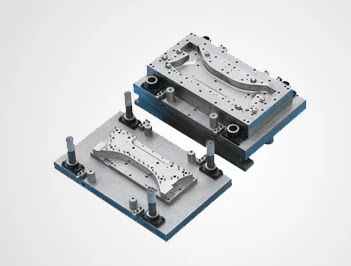

When

a metal sheet is fed into a powerful press, a specific design is formed. This

design is a replica of the desired

final part, and this process

is known as metal stamping.

This process is used

to create large quantities of identical parts. It is not only cost-effective

but also provides precise results.

It is a highly preferred method where precise dimensions and functionality are required.

What is Zinc Die Casting?

It is a high-pressure metal shaping technique. Zinc is a versatile and affordable metal that is melted before being used in this process. The molten zinc alloy is heated and injected into a precisely designed steel mould cavity under high pressure. This way, zinc die casting manufacturers let the molten metals settle into the mold's complex details and solidify to form a perfect final outcome.

What are the Benefits

of Custom Metal

Stampings and Zinc Die Casting?

Both processes are widely used in automotive, aerospace, electronics, and other industries. Let’s take a look at their benefits:

Custom Metal Stamping

- Metal stamping thrives in large quantities. Once the tooling is created, the process churns out identical parts rapidly, turning it ideal for mass production.

- While the initial die investment can be substantial, the cost per unit plummets with high-volume production. This makes stamping highly economical for large orders.

- Stamping delivers consistent parts with tight tolerances. This is crucial for applications with precise dimensions and functionality, such as automotive components or electronic parts, are paramount.

- Many metals can be stamped, from lightweight aluminum to high-strength steel. This flexibility allows designers to choose the most suitable material for their needs.

- Modern stamping techniques can handle simple bends and intricate folds. Parts with cutouts, embosses, and even threads can be efficiently produced using specialized tooling.

Custom Zinc Die Casting

- Die Casting Manufacturer delivers complex parts significantly faster than traditional machining methods. This is a major advantage for projects requiring rapid prototyping or quick turnaround times.

- While upfront tooling costs exist, die casting is a cost-efficient way to produce medium to large batches of parts compared to machining.

- Die-casting molds can be designed to create intricate geometries with thin walls, features that would be challenging or expensive to achieve through other methods. This opens doors for innovative and complex product designs.

- Die-cast parts often boast a smooth surface finish, reducing the need for additional finishing steps like polishing or sanding. This saves time and resources during the manufacturing process.

How to Choose Custom Metal Stampings

Suppliers & Manufacturers?

One

of the first things to consider when selecting a custom metal stamping supplier

or manufacturer is their level of experience and expertise in the industry.

Look for a company with a proven track record of producing

high-quality metal stampings and several years in the business. Experienced suppliers can provide valuable

insights and recommendations based on industry knowledge.

The quality

and precision of the metal

stampings produced by a supplier

or manufacturer are crucial

factors. Ask for samples of their work and inquire about the materials and

processes they use to ensure that the

end product meets your specifications. Look for suppliers with quality

control measures to ensure their

products' consistency and accuracy.

Another

important aspect to consider when choosing a custom metal stamping supplier is their ability to provide customization options. Whether you require specific

sizes, shapes, or finishes

for your metal stampings, ensure the supplier can accommodate your unique requirements. A supplier that can provide

customized solutions will be able to meet your

exact needs and deliver a product that aligns with your expectations.

Why should you consider

Metal Stamping Dies?

Both

stamping and die casting involve intricate processes with numerous factors to

consider. We are among the

best-known metal stamping suppliers and have the knowledge and experience

to navigate these complexities, ensuring efficient production and high-quality parts. We understand the properties of various metals and can recommend the most suitable

option for your specific needs, optimizing performance and cost.

We

prioritize rigorous quality control procedures throughout the process. We

ensure your parts meet all specified

dimensions, tolerances, and surface finishes, ensuring consistent quality.

We have the skills to minimize production defects and material

waste, leading to cost savings and a smoother production run. We

also prioritize safety protocols and operator

training, which reduces

the risk of accidents on the shop floor.

We

understand how to streamline the stamping and die casting production process, significantly reducing lead times and

production costs. We use advanced technology for tool design and production planning, like 3D modeling and simulation

software. This optimizes efficiency and helps identify

potential issues before they arise. We can handle both large and small production runs and adjust

our production volume

to meet your specific needs.

Are

you in need of high-precision, custom metal parts for your project? Look no

further than Metal Stamping Dies! We're a renowned manufacturer

with years of experience creating top-quality components for a wide range of industries. Our state-of-the-art facility

and expert team ensure efficient production and

competitive rates. Contact us today at (647) 294-5240 to discuss your project and see

how Metal Stamping Dies can transform your metal fabrication process!

Conclusion

Custom metal stampings and zinc die-casting manufacturing are flexible and cost-effective processes that can meet a wide range of

industrial needs. By understanding the manufacturing

process and choosing reliable metal stamping suppliers, you can ensure that your products are produced to the highest

standards of quality

and precision.

Comments

Post a Comment